Professor RYU Jeong-ho of Department of Materials Science and Engineering, development of ceramic heat treatment technol N

No.7742802- Writer PR team

- Date : 2023.09.26 14:53

- Publication Date : 2023.09.22

- Views : 7970

Significant reduction of process time and energy consumption with use of high-output light energy

Expectation of application to manufacture of flexible electronic components and semiconductors

Recognition of academic value through publication in an international renowned academic journal (Advanced Materials) in the field of new materials studies

[September 22, 2023]

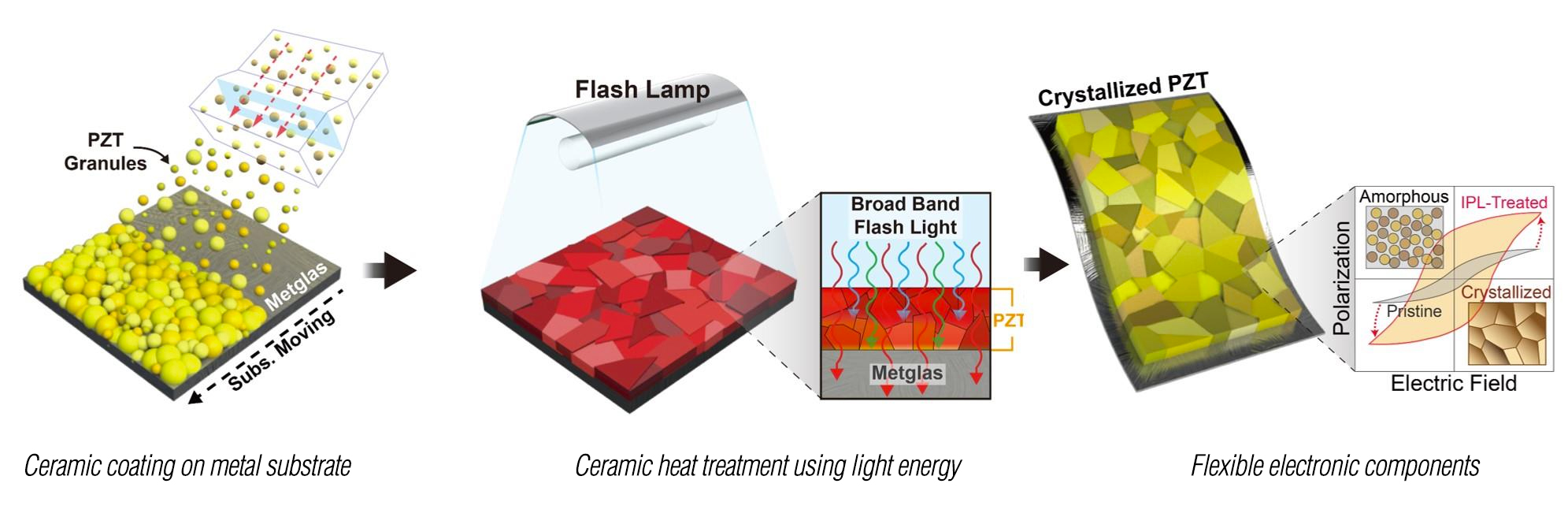

A joint research team led by Professor RYU Jeong-ho of Department of Materials Science and Engineering of YU (President CHOI Oe-chool) coated existing film-type ceramic materials on metal substrate and, instead of using high-temperature heat treatment, irradiated strong light similar to that used in a camera flash for 1/1000th of a second to produce ceramic material. As the result, high performance of ceramic materials were obtained, attracting attention from academia and industry.

More than 70% of electronic device components such as smartphones, tablets, computers, and TVs are made of ceramic materials.Recently, due to miniaturization and high performance of electronic devices, electronic components using ceramic materials are also being used by forming them on a substrate in the form of a thin film. However, in general, in order to properly realize the characteristics of ceramic materials, they are manufactured (sintered) with heat treatment of raw materials at high temperature of over 1,000 degree and the types of substrates to be used as base materials for the film were limited.

Professor RYU's research team succeeded in development of technology to heat-treat ceramic films without any influence to heat-instable metallic substrates by momentarily exposing the ceramic film to high-output light energy using xenon gas discharge.By developing flexible electronic component manufacturing technology that was impossible with existing high-temperature heat treatment methods, the characteristics of the device were significantly improved. Through the development of this technology, which enables large-area heat treatment with instantaneous light in a simple structure, it is possible to overcome the disadvantages of processes that took dozens of hours using existing expensive laser equipment or using traditional electric furnaces and it is expected that the potential for commercial application will be high.

<Overview of heat treatment technology for flexible ceramic thin film materials using high-energy light>

<Overview of heat treatment technology for flexible ceramic thin film materials using high-energy light>

Professor RYU said, “We have developed a photothermal treatment technology that dramatically reduces the time and energy consumption required in the high-temperature heat treatment process of existing electric furnaces and overcomes the limitations of the substrates that make up electronic components. It is expected to be applicable not only to manufacturing parts with optical, electrical, and magnetic properties of ceramic materials on polymer substrates or flexible metal substrates, which are essential for the development of flexible devices that can be attached to the human body, which have recently attracted attention, but also to semiconductor heat treatment processes.

This study was conducted through the National Research Foundation of Korea's mid-career researcher support project and was jointly conducted by Professor RYU Jeong-ho of YU, Professor PARK Jeong-hwan of Kumoh National Institute of Technology, Professor HWANG Geon-tae of Pukyong National University, and Professor Priya of Pennsylvania State University.The research paper was published on August 10, 2023, in the world-class academic journal <Advanced Materials, Impact Index (IF) 32.086> in the field of new materials studies, and was recognized for its technological originality and academic merit.